![]()

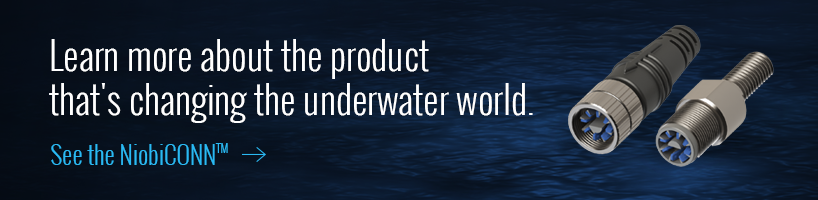

This is the first in a six-part series as we take an in-depth look at how NiobiCONNTM performs in various applications and can provide solutions no other connector can.

Few things contradict as strongly as water and electricity. Nonetheless, electrical engineers have found ways to conquer Earth’s aquatic frontiers, but not without shouldering the tremendous risks, responsibility, and challenges of working in some of the most damaging and dangerous environments on the planet. Fortunately, electrical components have evolved significantly to enhance the safety and efficiency of underwater power and signal systems. Arguably one of the most noteworthy advancements is the development of an electrical connector that prefers the ingress of water.

The Power of NiobiCONN™ Technology

Niobium is a metallic chemical element similar in strength to titanium and conductivity to copper or aluminum alloys, but with an entirely different reaction to water. Niobium is similar to titanium in terms of corrosion resistance. The combination of H2O and volts causes niobium contacts to create their own passive film when energized and exposed to water. The film acts as an insulator, electrically isolating the contact from the surrounding water and adjacent contacts.

The insulating anodic film on the niobium contact mating surface is breached as the contacts are mated, providing electrical connectivity. In the areas where the niobium contact insulating anodic film is removed during mating, it is instantly restored as soon as unmating occurs.

The Benefits of NiobiCONN™ Wet-Mate Connectors

Niobium connector contacts are touch-safe in or out of the water and do not require facial seals or oil gaskets, which can create a failure point, making a connector more vulnerable to damage. Due to its unique relationship with water, niobium connectors are 100% resistant to corrosion and can provide reliable connectivity at any depth.

How NiobiCONN™ Power & Signal Cables Support Extreme Applications

![]()

Autonomous Underwater Vehicles

Autonomous or unmanned underwater vehicles (AUV/UUV) run on batteries, limiting the duration of power available for time-consuming missions. Today, engineers use niobium connectors in docking stations to make recharging or even replacing AUV/UUV batteries while fully submerged possible. With underwater charging capabilities, missions can move forward with greater efficiency, fewer time constraints, and with far less risk of electrical failure.

Aquaculture & Fish Farming

Maintaining a safe and hygienic pond environment is crucial to raising healthy fish. Electrical failures represent a common disturbance for fish farm operations, which heavily rely on pumps, filters, and monitoring equipment to maintain homeostasis in pond environments. Occasionally such electrical failures can result in large-scale loss. With innovations such as niobium power and signal connectors, aquaculture technology can support underwater operations with greater efficiency while reducing risk and maintenance needs.

Underwater Lighting & Video Monitoring Systems

From off-shore drilling equipment and bridge construction to pipeline or well monitoring and inspection, underwater lighting and video monitoring systems allow engineers to see in places that they cannot physically go. As the only source of information in critical operations, equipment reliability is paramount. Water ingress poses a significant threat to underwater technology, especially in applications that do not support wireless connectivity. Niobium connectors improve the quality and stability of power or signal transmission and dramatically reduce the time and cost associated with maintaining these systems.

Underwater power and signal connectors are not the only extreme application for iCONN System’s all-new NiobiCONN wet-mate connector.